Tenaih combines the expertise in processing viscose, modal and lyocell materials with decades of experience in knit fabric dyeing and printing. Our knowhow has been extended from Tencel lyocell fiber A100 to LF and G100 for knit fabrics, which is continuously upgrading and expanding our fabric collections with this sustainable material for elegant, versatile and comfortable clothing designs.

Lyocell, widely known since Lenzing promoted it under the Tencel brand, is a key material in our knit fabrics. Its high wet modulus is conducive to the shape retention of the fabric, whether in light-weight single jersey, medium-weight interlock, or heavyweight ponte. Lyocell fiber fibrillates after wet processing, producing a luxurious and soft-touch fabric with a micro-peach skin or sandwashed effect. The fibrillation parameters can be adjusted to achieve the desired look and feel of Lyocell knits for both prints and solid colors. Tencel G100 can serve as a replacement for either the LF or the A100 in our fabric design. Our know-know in preventing white scratch marks on lyocell knit fabric is what allows reactive dyes to achieve their brilliant colors on this outstanding material. Dresses are the most common use for our lyocell fabrics. Lyocell dress drapes elegantly and subtly for an elegant look and feel.

We use Lenzing Modal (MicroModal or MicroModal Air) only and produce three fabric lines. One is traditional knits in printed and solid thanks to its brilliant color performance and extremely soft to skin. Another is the Sandwashed Modal Polyester Scuba and Jersey. The Sandwashed Modal gives not only soft-to-skin but luxuriously cozy touch. The newly added line MicroModal Air Voile is an extraordinary option for Summer tops and dresses. It's like silk but matte.

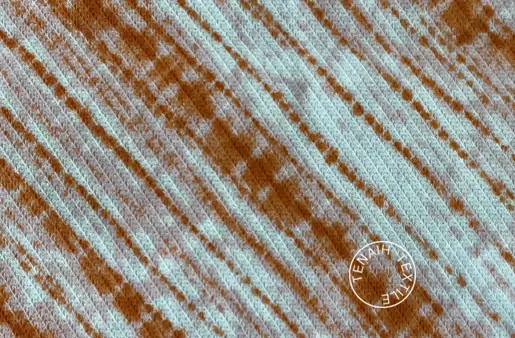

Screen printing has the advantage of color penetration for its depth, saturation via pressure and screen adjustments, comparing to digi or rotascreen prints. Whether for allover print or engineered print, we care the joint quality of each roll and cleanness of the PFP fabric before and throughout printing process, which lead to a clean printed fabric with consistent dimensional stability and good skewness. Standard Lyocell Ponte printing is in progress after fibrillating pre-treatment as below image.

Flat washing secures the colors would be utmostly even after bulk washing. We care each and every color of a print and pay close attention in washing process for reactive print or reactive + pigment print.

We love life and vibrant prints for life. We care each and every print we produce as our life. Decades of printing production experience helps us to execute good color matching and registration, presenting the effect that the designer wants to achieve.